Heat2Power: a hot new startup that converts stored heat into electricity

Heat2Power, co-founded by Profs. Stephen Forrest and Andrej Lenert, uses high-efficiency, low-cost thermophotovoltaic technology to turn stored heat into energy.

Heat2Power, co-founded by Profs. Stephen Forrest and Andrej Lenert, uses high-efficiency, low-cost thermophotovoltaic technology to turn stored heat into energy.

Written by Catharine June

A new startup company called Heat2Power (H2P) holds the key for low-cost, efficient generation of energy from stored heat. Its core product, based on thermophotovoltaic (TPV) technology, is a modular panel capable of turning heat into power. The company’s technology will help provide power to industrial users at rock-bottom prices, in an environmentally friendly way.

Heat2Power was founded by an experienced interdisciplinary team at the University of Michigan who are leveraging years of technology development to bring their patented ideas to market. Co-founder Stephen Forrest, Professor of Electrical Engineering & Computer Science, Physics, and Materials Science & Engineering, is a renowned leader in optoelectronics, and a highly successful entrepreneur whose innovations have led to five companies. Co-founder Andrej Lenert, Associate Professor of Chemical Engineering, brings extensive experience in thermophotovoltaic energy conversion.

“Thermophotovoltaic devices are very much like solar cells, except they convert heat, as opposed to sunlight, to electricity,” said Forrest, the Peter A. Franken Distinguished University Professor of Electrical Engineering and Paul G. Goebel Professor of Engineering.

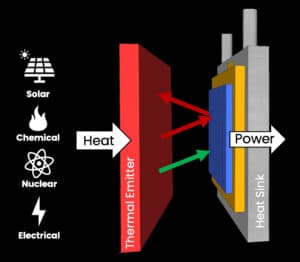

This graphic shows a basic thermophotovoltaic (TPV) system. An energy source such as solar, chemical, nuclear, or electrical, generates heat that gets fed into a heat storage container. The thermal emitter releases that stored energy and a TPV cell converts it into electrical power.

Heat2Power’s highly-efficient TPV devices can be paired with high-temperature thermal energy storage (TES) systems to add economical and sustainable on-demand capabilities to sustainable energy sources such as wind and solar, as well as provide an economical way to recycle the wasted energy typical in industrial power plants.

Both markets have tremendous potential.

“The amount of energy in California alone that is generated by solar but ultimately is wasted because it can’t be stored would power about 300,000 homes,” said Forrest.

And while industry accounts for about 30% of all U.S. energy consumption, it also wastes about 20-50% of the energy consumed in the form of heat.

Currently, in order to make wind and solar energy available on demand, it is typical to resort to methods such as pumped water, which requires expensive hydroelectric facilities, or lithium-ion batteries, which are expensive and generate toxic materials waste. In the industrial sphere, plants that require high temperatures for operation are moving to thermal energy storage (TES) systems to store the heat for later use.

There is an entire industry devoted to TES systems. Heat2Power directly serves this industry, and has the technology to greatly enhance its effectiveness.

A primary component of TES systems are large storage containers that store the thermal energy. Heat2Energy’s TPV panels would line the interior of the containers, and when energy is needed, the heat would be released to radiate to the panels.

“The thermal radiation that’s coming off the hot storage material is collected by our TPV panels and converted into electricity almost instantaneously,” said Lenert.

Heat2Power’s TPV technology converts heat to electricity more efficiently than any current device on the market at scales ranging from kWs to MWs. Its efficiency is also stable across a wide range of temperatures, while other current technologies become inefficient at lower temperatures.

“We pioneered the first solid-state power generator with over 44% heat-to-power efficiency and a clear path to over 50%,” said Forrest.

At the center of Heat2Power’s technology is its patented technology called air-bridge thermophotovoltaics, developed by the team. With this technology, it is possible to harvest thermal energy even at the relatively low temperatures that reactors put out.

Companies that work in energy storage and waste heat recovery spaces are already showing interest.

“We have more customers for this than we can currently serve,” said Forrest.

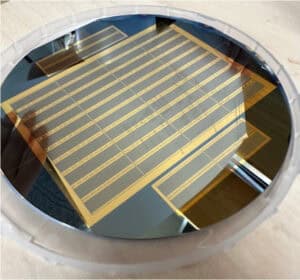

Heat2Power has raised funding, with the goal of showing a demonstration product within two years. Their device is compatible with existing semiconductor manufacturing processes.

“It’s exciting to see something that we developed in the lab align with customer needs, and to be used for something that’s beneficial to society,” said Lenert.

Heat2Power was launched in 2024 with the help of Innovation Partnerships. In January 2025, the Accelerate Blue Fund, an early-stage venture fund that exclusively invests in U-M licensed startups and is managed by Innovation Partnerships, invested in Heat2Power.

The device was developed in the Lurie Nanofabrication Facility at the University of Michigan.

Key publications that provide details of the technology: