Accelerating innovation with machine learning

Chemical Engineering faculty and students are using machine learning to open up new possibilities in research.

Chemical Engineering faculty and students are using machine learning to open up new possibilities in research.

From predicting the solubility of molecules to accelerating complex data analysis, machine learning (ML) is revolutionizing chemical engineering research. Faculty and students are harnessing artificial intelligence to accelerate discoveries in energy, materials science, and healthcare—reshaping how we design new technologies and solve complex challenges.

In the Goldsmith Lab, researchers are using machine learning to design novel molecules and materials for energy storage, catalysis, and sensing. Led by Associate Professor Bryan Goldsmith, the lab focuses on several projects. Among them is the use of reinforcement learning and advanced generative modeling techniques to generate organic molecules for redox flow batteries, a critical component of energy storage systems.

“Foundation models built with diffusion models, flow matching models, and transformer-based architectures can be applied to a wide range of downstream tasks,” said postdoctoral fellow Weichi Yao, who works in the lab. “In particular, we focus on novel molecules/materials generation with these tools.”

The lab also explores the use of interpretable machine learning and generative modeling methods to better understand heterogeneous catalysts, as well as to predict the solubility of organic molecules and to decipher sensor data for applications in wastewater treatment.

Many of these projects are in collaboration with other Chemical Engineering faculty, such as Professor Suljo Linic, Professor Nirala Singh, and Professor Mark Burns.

The Lindsey Lab is developing tools that bridge the gap between computational efficiency and accuracy in molecular simulations.

“We develop machine learning (ML) and artificial intelligence (AI) tools that enable ‘quantum accurate’ particle-based simulations on unprecedented scales, often overlapping with experiment,” said Assistant Professor Rebecca Lindsey. “These tools enable a previously-inaccessible view into the microscopic phenomena governing behavior of chemical and material systems and thereby provide critical insights for design and scalable synthesis of next-generation materials.”

Graduate students in the lab are applying these tools to various challenges in materials research.

“The Lindsey Lab develops the Chebyshev Interaction Model for Efficient Simulation (ChIMES), a machine-learned interatomic interaction model and AI-driven development framework targeting chemistry in condensed phase systems,” said second-year postdoctoral student Benjamin Laubach. “This framework is being applied to a wide variety of systems in our lab, spanning design of novel membranes for sustainable ammonia synthesis to establishing novel high-throughput methods for synthesis of next-generation nanomaterials.”

Melody Zhang, a third-year PhD student, is extending the Lindsey Lab’s ChIMES model to construct a high-dimensional design surface that predicts interactions between nanoparticles and enables inverse design of hierarchical structures they can self-assemble into.

“The value of using AI and ML in my research is profound. These tools allow me to explore high-dimensional design spaces that incorporate detailed chemical and physical information,” said Zhang. “Ultimately, the integration of AI in my research not only accelerates the discovery and design of new materials but also paves the way for the development of more robust predictive models that could be adapted to a wide range of industrial applications.”

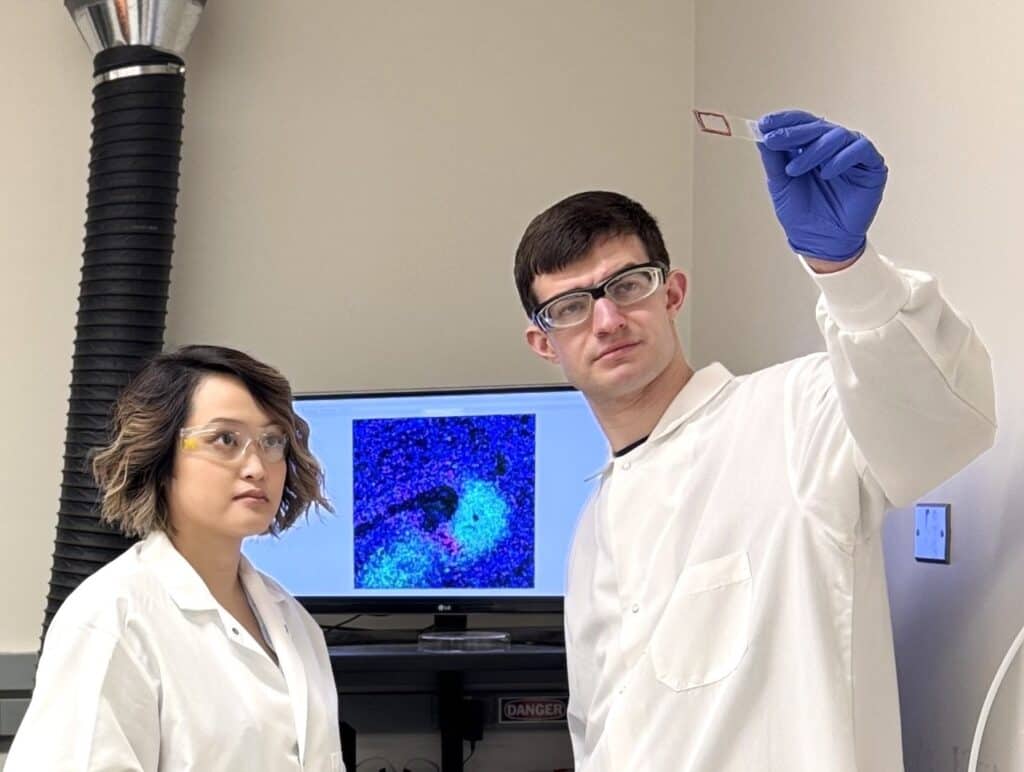

The impact of machine learning extends beyond materials science into healthcare applications. The Wen Group is leveraging AI to understand human immune responses at the single-cell level.

“We are using machine learning to understand the immune responses in disease and treatment, particularly in our Cytometry by Time-of-Flight (CyTOF) studies, due to the complex, high-dimensional data that this technique generates,” said Professor Fei Wen. “CyTOF can measure approximately 40-100 proteins simultaneously across thousands to millions of single cells, making it an exceptional tool for dissecting immune cell heterogeneity, phenotypes, and signaling pathways in detail. This volume and complexity of data require advanced computational approaches such as machine learning for meaningful interpretation.”

Wen’s team is developing machine-learning-based graphical user interface (GUI) software that not only accelerates this data analysis, but also makes these sophisticated analytical tools accessible to the broader medical research community.