Engineering Matter By Design

A strategic direction for research

We are leading a revolution in transformative manufacturing of integrated multimaterials systems that assemble from the bottom up, building on our leadership in nanoscience. Bioinspired materials made by design and on demand have the potential to transform every industry and benefit every person on the planet. This body of knowledge is key to a sustainable future.

A revolution in materials design

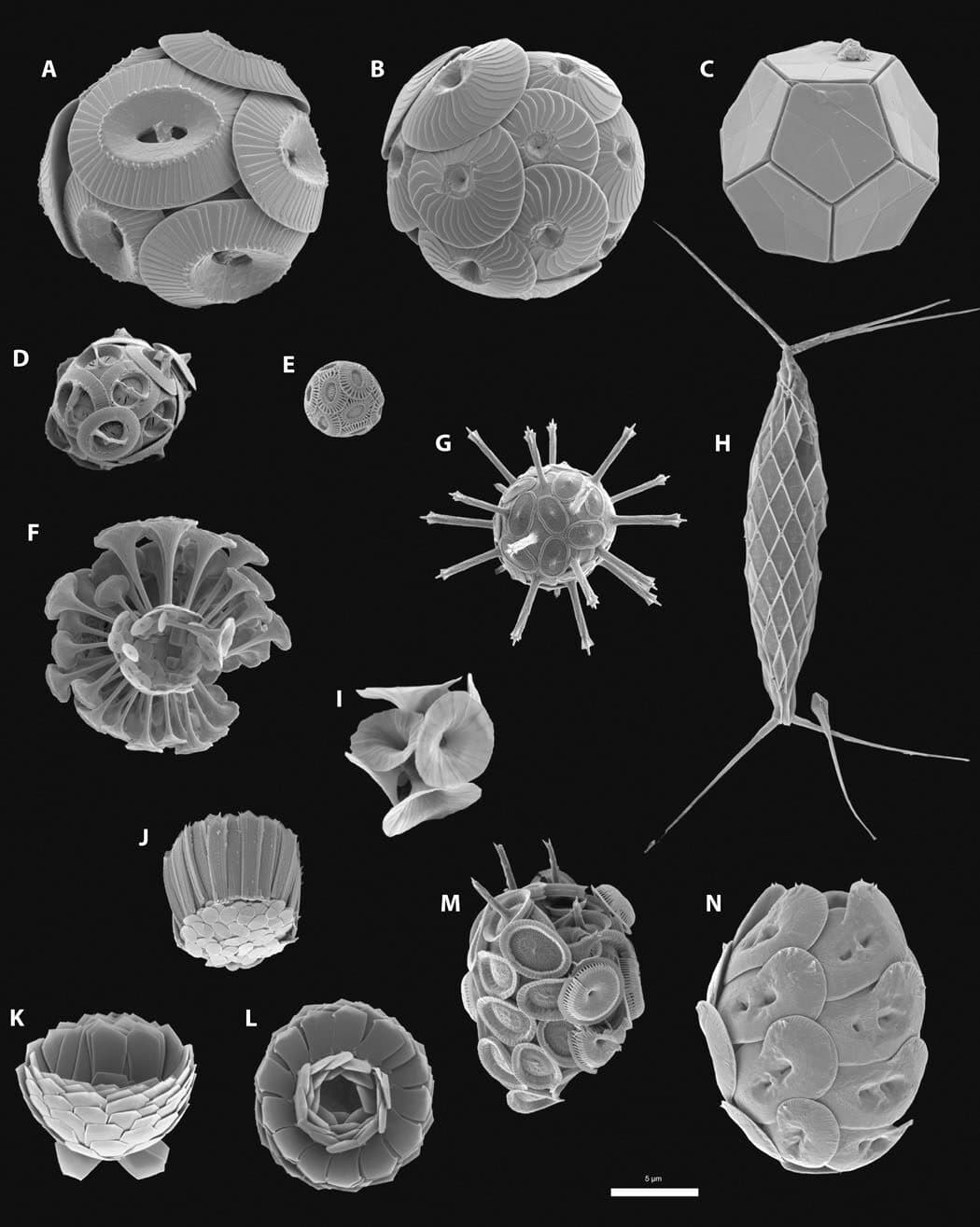

From bronze and iron to ceramics and glass to plastics to silicon chips, society has been shaped by the materials we’ve mastered. However, tomorrow’s world will not be shaped by the discovery of – or mastery over – a single new material. Instead, tomorrow’s materials will be integrated multimaterial systems designed and engineered from the bottom up. Nanoscience and nanotechnology have provided new tools and paradigms for designing materials systems that build themselves. Combined with additive manufacturing techniques that use physical space and time to guide the formation of solids from flowable materials, novel materials with unprecedented properties are close at hand. Yet material design is still limited by poorly understood processes, and the complexity of material properties still pale in comparison with what biology provides.

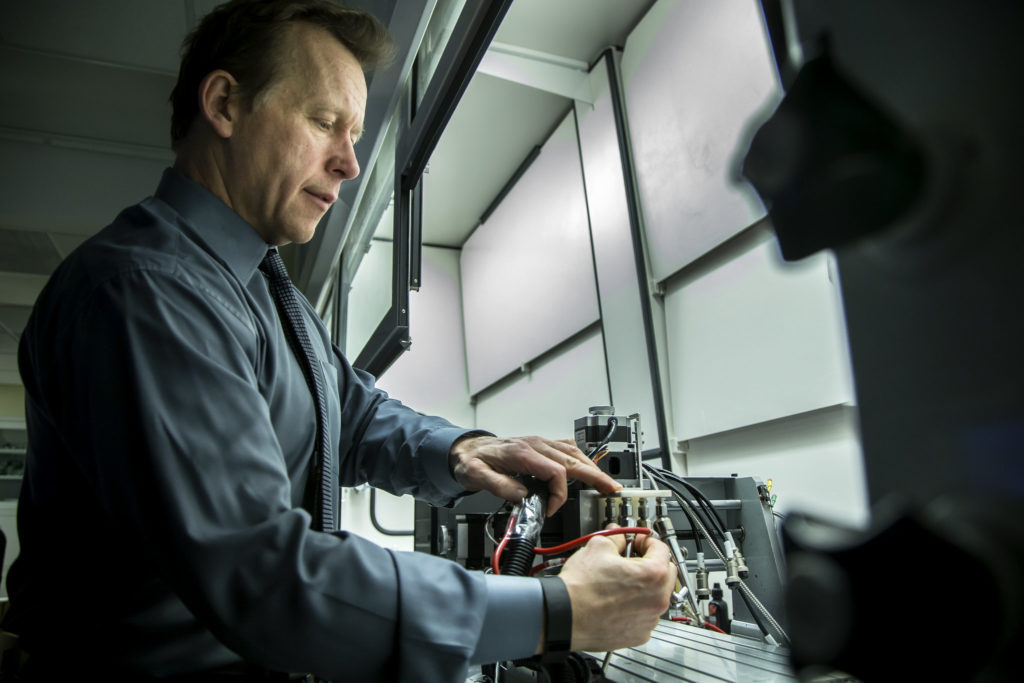

Michigan ChE is taking matter by design to the next level. The convergence of ideas from chemistry, physics, biology, network science, mathematics, materials science, nanotechnology, mechanical engineering and chemical engineering, together with AI, exascale computing and new imaging tools with unprecedented resolution, both spatial and temporal, have set the stage for a materials revolution. Through COMPASS, a new $30M NSF-funded Science & Technology Center on Complex Particle Systems, Michigan ChE is leading this revolution. Designer materials, precisely engineered and manufactured on demand from imprecise nanoscale building blocks, where and when they are needed, will impact life across the globe, create seemingly impossible solutions, and make possible currently unimagined new technologies.

Imagine a world where:

- Human-made materials are programmed with functionality that rivals that of biology.

- Materials are self-assembled on-demand and made to order at point-of-use with zero waste.

- Materials programmably change shape, function and decompose, enabling a circular economy.

That world is on its way thanks to Michigan chemical engineers.

WHY MICHIGAN

The University of Michigan’s deep expertise in manufacturing and strong relationships with key industry, government, economic and partner organizations put us in a central position to move the needle in a state that historically leads innovation in manufacturing.

OUR RESEARCH:

MIMICKING THE NATURAL WORLD

We are inventing new materials inspired by the natural world. We have made impossible leaps in electric battery capacity possible, through the invention of precise, cost-effective, environmentally friendly materials.

1,000-cycle lithium-sulfur battery could quintuple electric vehicle ranges

DEVELOPING NEW WAYS TO STRUCTURE MATTER ACROSS SCALES

Our researchers are using computer simulations to make the structure of ‘fire ice’ with nanoparticles, potentially opening doors to manipulate light in new ways.

The study showcases an unusual effect that the team is calling entropy compartmentalization.

COMPASS – CENTER FOR COMPLEX PARTICLE SYSTEMS

The NSF has provided $30M over five years to a multidisciplinary team of researchers led by Professor Nicholas Kotov, including seven Michigan Chemical Engineering faculty members. The Center aims to learn how to design materials by describing nanoparticle assemblies as systems that ladder up through the microscale to the macroscale.

Largest U.S. investment in particle self-assembly seeks to deliver on nanotechnology’s promise

Recent news in MATTER BY DESIGN:

-

Nurturing high-risk, high-reward ideas

Sunitha Nagrath received Bold Idea funding from the Rogel Cancer Center’s Forbes Institute for Cancer Discovery that provided critical seed funding for research breakthroughs.